Our production facilities

Serving the food industry since 1969, we recognize the crucial importance of delivering ingredients to you promptly and upholding the quality standards you expect from us. This is why we source raw materials from various locations and carry out manufacturing at multiple sites, ensuring the fulfillment of your orders even in the face of production challenges in specific areas.

Maintaining multiple production sites in both Europe and the Americas provides the flexibility required by global food producers today.

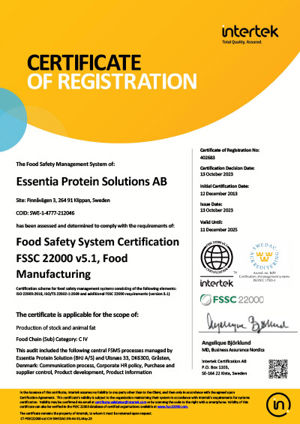

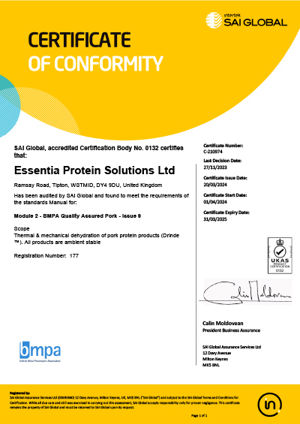

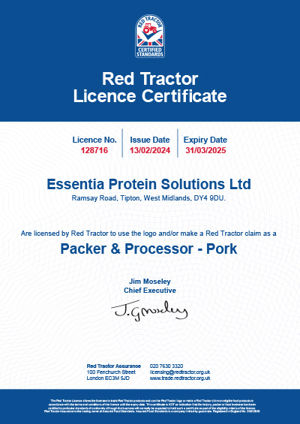

As a highly accountable supplier, we are deeply committed to offering complete traceability and ensuring unwavering quality. We implement globally recognized Quality Assurance (QA) and food safety systems that align with the highest standards. In addition to mandatory documentation, our QA and regulatory specialists provide valuable insights on declaration issues and import/export restrictions, aiming to facilitate the fastest time-to-market for our customers.

Granollers, Spain

State of the art technology

At our food-grade plant in Granollers, we produce powdered functional proteins for meat applications. These functional proteins are derived from porcine blood, red cells, and plasma, which are inherent by-products of pig slaughtering. We collect and process pork blood and reintroduce it into the food market with very specific properties that add value to the meat processing industry. Among our diverse product range, AProRed™ stands out as a truly distinctive offering, being a natural coloring food derived from red cells that naturally enhances the color of meat.

Since the plant was built in 1981, it has consistently evolved, undergoing expansions and renewals. A significant milestone occurred in 2018 with the construction of an entirely new food-grade blood plant. Equipped with state-of-the-art technology, this facility prioritizes food safety, quality, and sustainability. Notably, all water recovered from the production process undergoes treatment in our wastewater treatment plant, enabling its reuse.

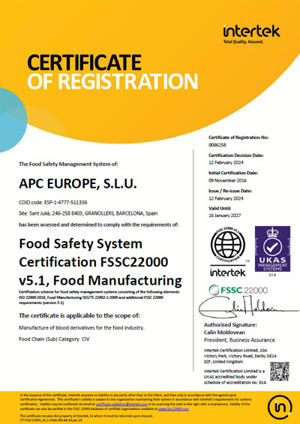

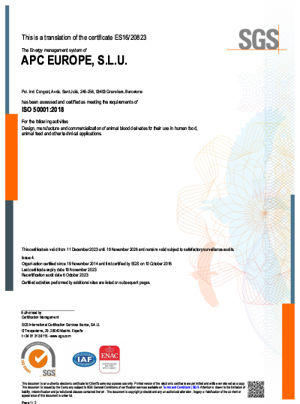

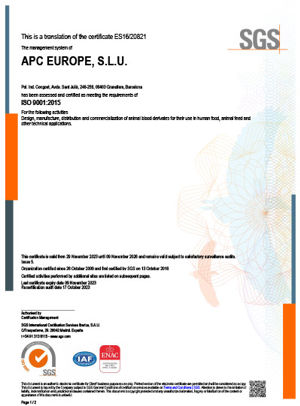

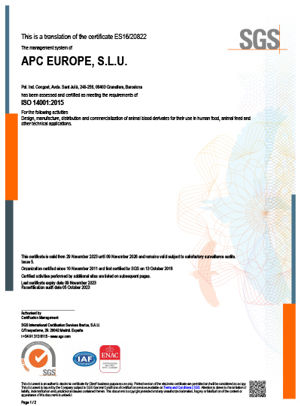

View our documents of accreditations

Certificates for our Granollers facility

Gråsten, Denmark

Functional proteins and pork pellets since the 1980s

Our Gråsten facility was built in 1980 and fully commissioned in 1981. Production of functional proteins derived from pork rind took off in 1982. The plant was expanded in 1988 with a new warehouse and a new packing line and recently the facility had a new cooker installed.

The facility manufactures functional proteins and pork rind pellets for high protein snack products.

Gråsten has taken a pioneering step towards sustainability by transitioning its Nitrogen consumption to 100% green Nitrogen and sourcing 50% of its electricity from renewable sources.

View our documents of accreditation

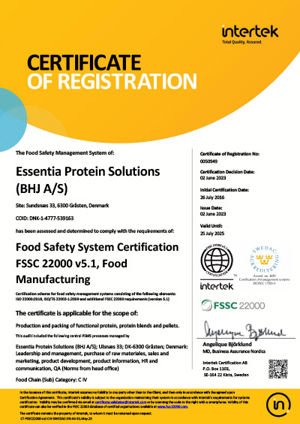

Certificates for our Gråsten facility

Hobro, Denmark

Transforming pork rind into best-in-class ingredients

The production facility in Hobro (Denmark) was acquired in 1991 from Grindsted Products (Danisco). At that time as also today, the plant produced functional and high functional proteins derived from pork rind. In addition, the site included a soup stock line. In 1996, the processing equipment for the soup stock production was moved from Hobro to our facility in Stidsvig (Sweden).

Our Hobro facility underwent a major refurbishment from 2008 to 2010 and has undergone continuous expansion ever since.

The know-how and expertise invested in the Hobro facility positions it as a global leader in the production of high functional proteins derived from pork. The exceptional water-binding and gelling properties of the Hobro range sets a true benchmark in this ingredient category.

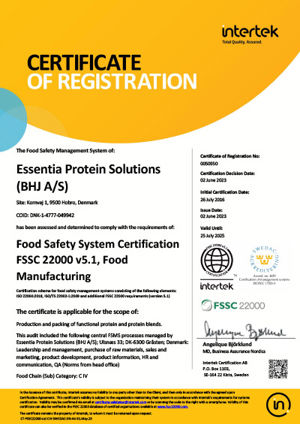

View our documents of accreditation

Certificates for our Hobro facility

Højmark, Denmark

Fish and seafood stocks packed with flavor and expertise

Close to the North Sea on the west coast of Denmark and adjacent to several key ports, our Højmark production facility specializes in manufacturing soup stocks cooked from fish and seafood raw materials. The Højmark facility was acquired by Essentia Protein Solutions in 2015.

Since 1984, the company has operated as a research and consultancy business known as the Hojmark Group. In recent years, it has focused on producing high-quality soup stocks based on some of the finest marine raw materials, including cod, plaice, lobster, and mussel. All raw materials come from wild catch primarily in the waters around Scandinavia. Most products are available as chilled or frozen liquid pastes.

View our documents of accreditation

Certificates for our Højmark facility

Nordhorn, Germany

Collagen peptides and tailormade ingredient systems

The Nordhorn factory is a modern blending and manufacturing facility specializing in processing a diverse array of ingredients for customized functional compounds tailored for the meat industry. These functional ingredient systems typically blend functionality from both animal- and plant-based proteins with various hydrocolloids. Additionally, the factory features an impressive section dedicated to the production of collagen peptides derived from natural bovine and porcine raw materials. These raw materials undergo enzymatic hydrolysis, wherein protein strands are cut into rapidly absorbable peptides.

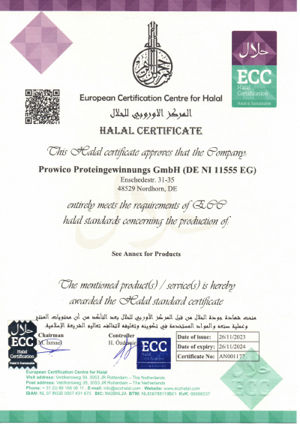

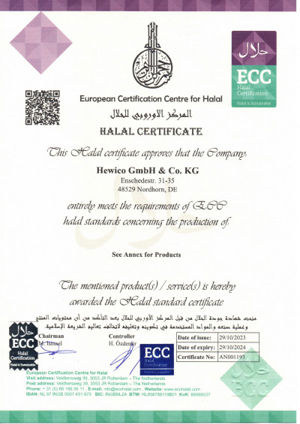

View our documents of accreditation

Certificates for our Nordhorn facility

Stidsvig, Sweden

A modern soup stock facility

The Stidsvig production site was acquired from Swedish Quality Meat in 2006, initially focusing on the production of edible fats, meat and bone meal, and edible greaves. Today, Stidsvig has been transformed into a state-of-the-art manufacturing facility specializing in stocks, broth, and edible fats for the savory sector.

Over the years, we have continually upgraded the plant for refining our raw materials e.g., with a fat-refinement facility incorporating deodorization and fractionation processes.

In the period between 2019 and 2023, significant investments were made to modernize the facility. Additionally, there was a 100% capacity expansion for the extraction process. The plant underwent upgrades and implemented compression technologies across all main steam consumption points, resulting in a remarkable 90% reduction in our CO2 footprint in this specific area.

View our documents of accreditation

Certificates for our Stidsvig facility

Tipton, UK

A facility with consecutive high ratings

Since 1969, our UK plant in Tipton, West Midlands has been manufacturing DrindeTM, an originally patented functional ingredient derived from dehydrated pork rind. Then in 2003-4, a major refurbishment and expansion took place to bring fine milling to the UK plant.

Our on-site warehouse gives us the capacity to ensure that we maintain full control of our product before it is shipped out to customers.

The facility has for over 20 consecutive years achieved the highest rating as a BRC AA grade site. It also holds a BQAP (British Quality Assured Pork) assurance, Red Tractor Farm Assurance, and BRC Voluntary Module 11; the perfect accreditation criteria for manufacturers looking to offer ‘Quality British Food’.

View our documents of accreditation

Certificates for our Tipton facility

Get the basics about who we are and what we do

Dig deeper into Essentia

Who we are

Learn more about how individuals work towards Essentia’s goals as well as their own, and why finding a balance between the two is necessary.

Meet an employee

Get firsthand experiences and perspectives from some skilled professionals as they share their thoughts on being part of the organization.

Part of something bigger

Essentia Protein Solutions, owned by the Lauridsen Group Incorporated (LGI), is the result of a merger between three significant protein specialists.